Summary

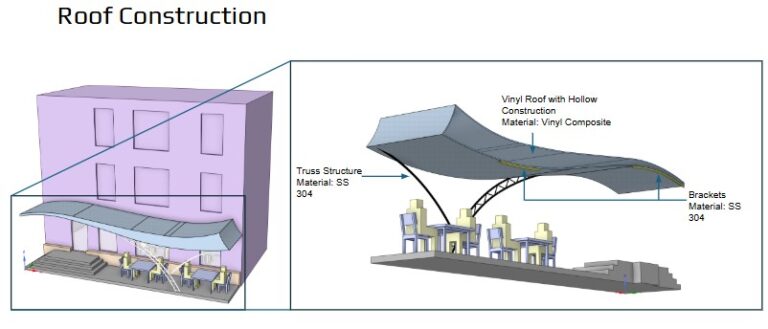

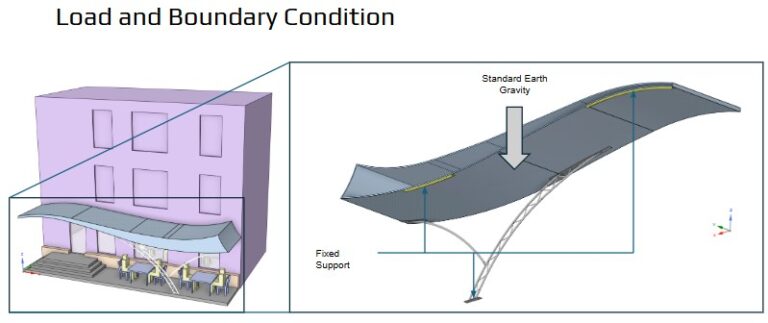

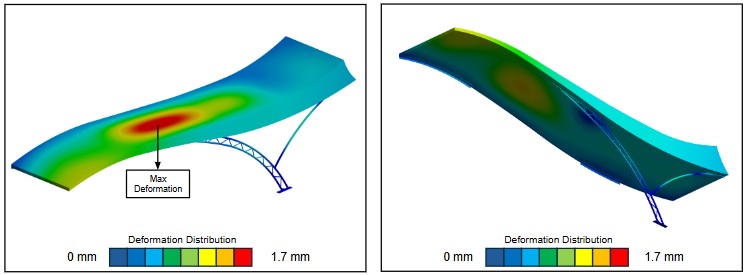

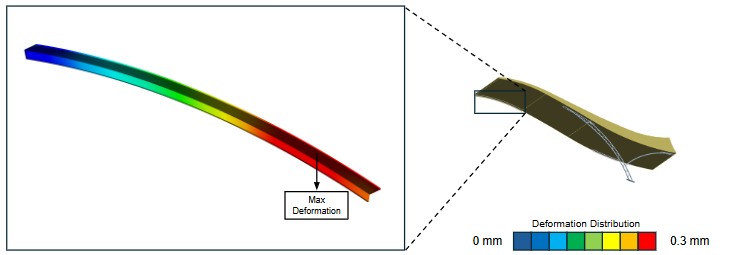

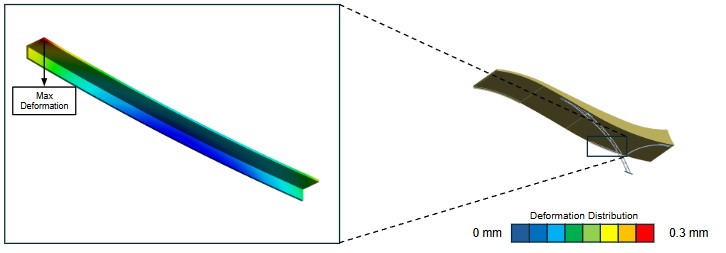

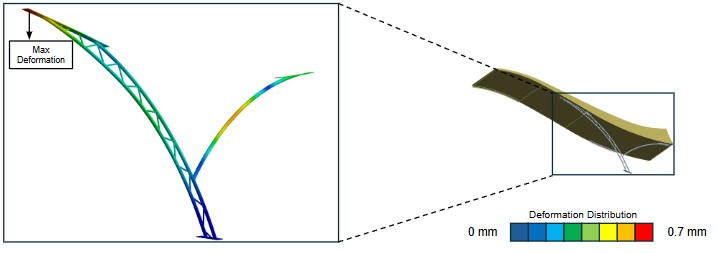

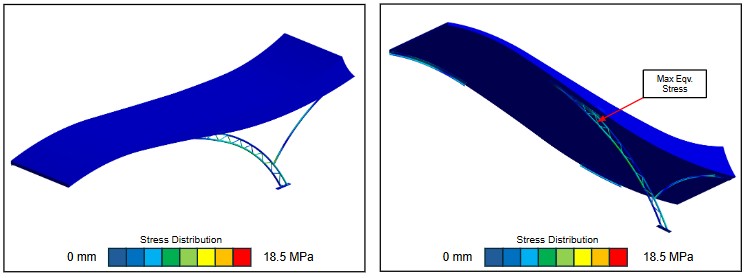

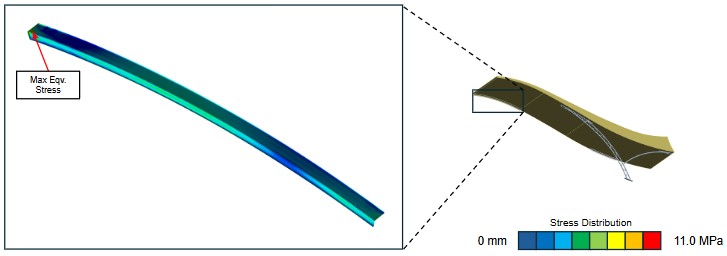

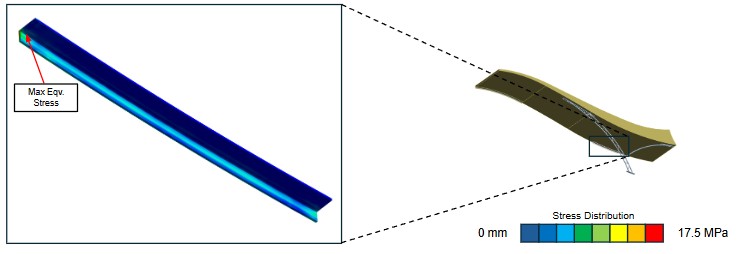

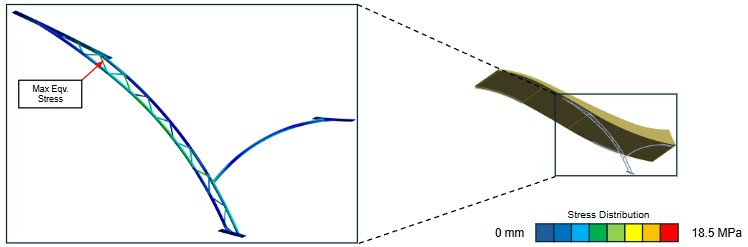

This study presents a comprehensive numerical evaluation of a proposed roofing/awning structure using Finite Element Analysis (FEA). It assessed the structural integrity of the system under governing load cases, providing detailed insights into deformation, stress distribution, and overall structural safety.