Summary

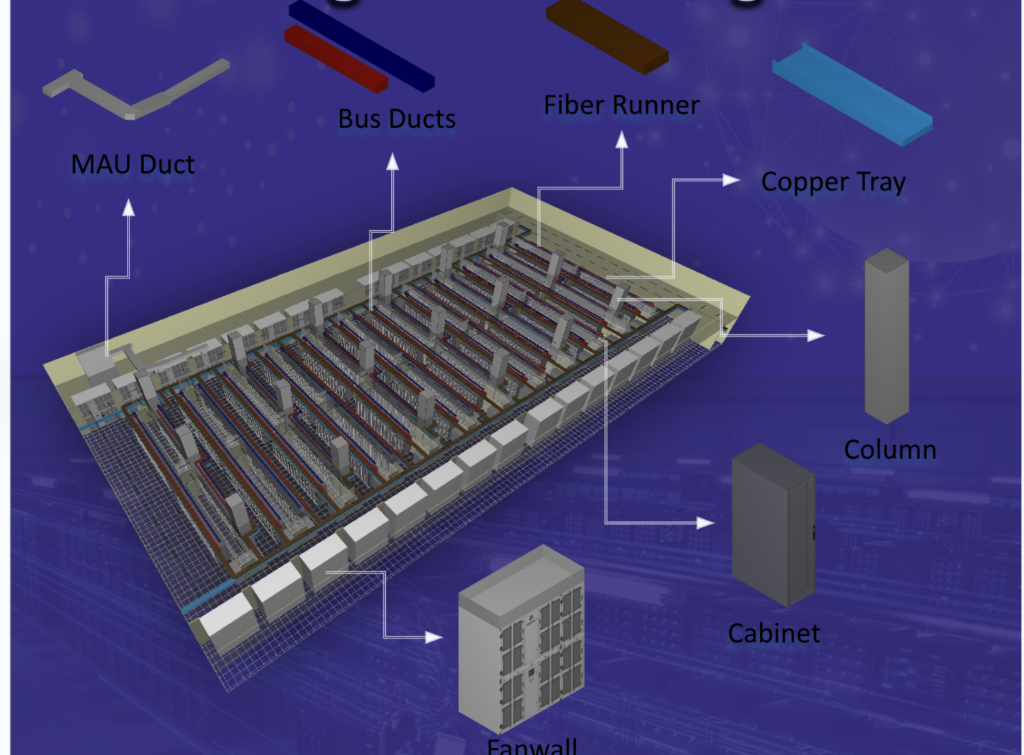

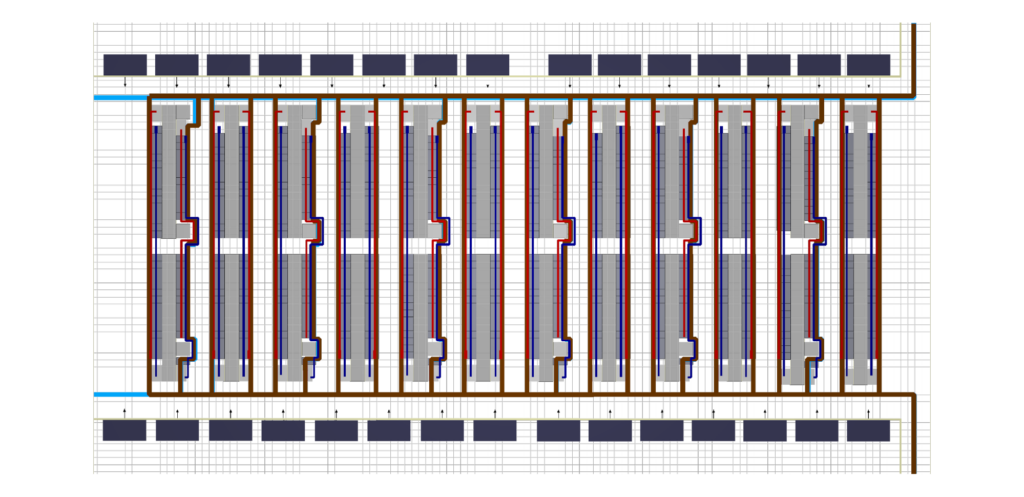

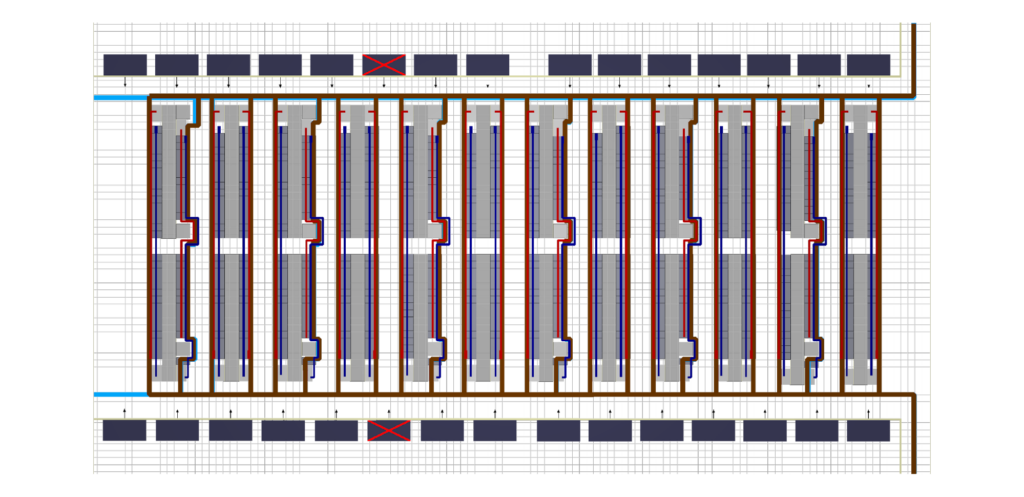

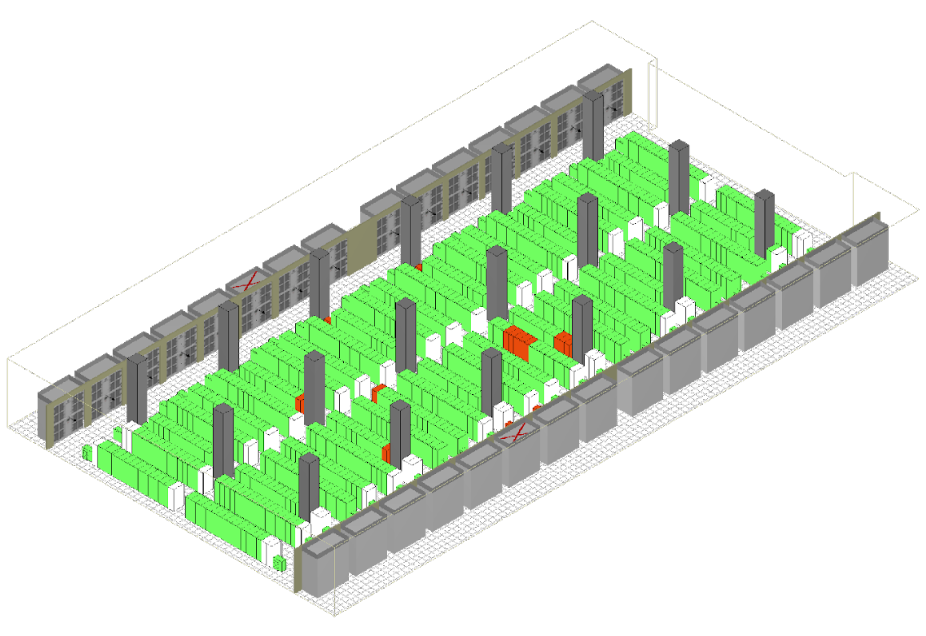

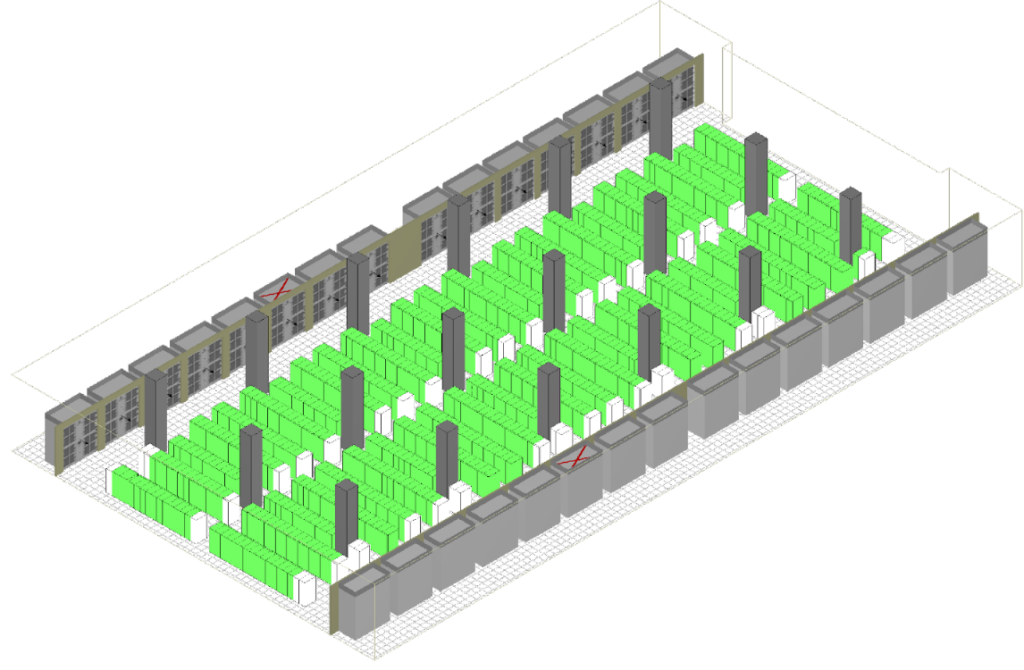

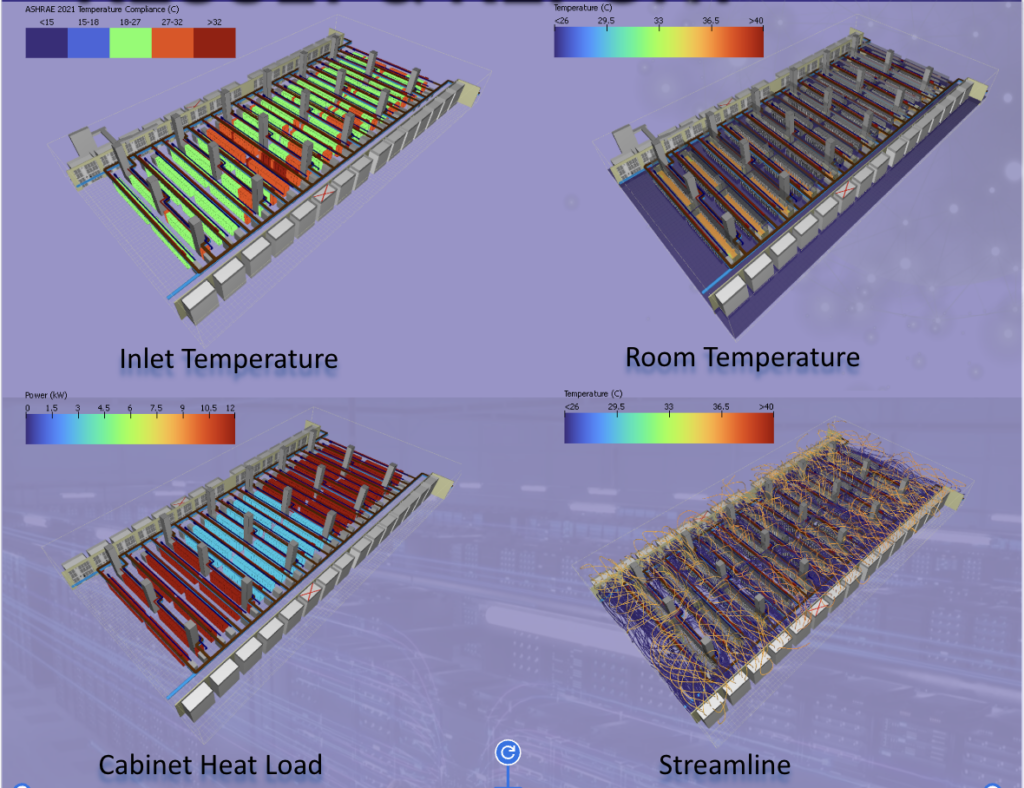

This case study demonstrates how Computational Fluid Dynamics (CFD) was used to optimize airflow and temperature distribution in a data center. By simulating both normal and contingency operating conditions, engineers identified inefficiencies, reduced hotspots, and validated the cooling system design to ensure reliable, energy-efficient, and sustainable operation.