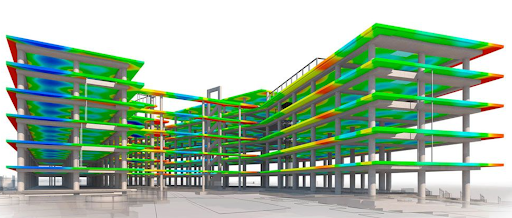

Finite Element Analysis

FEA Service Singapore

Our Finite Element Analysis (FEA) services give you a detailed assessment of how structures respond to real-world conditions such as applied loads, vibration, heat, fluid interaction, and other physical effects.

By applying industry-proven methodologies, we give you clear, data-driven insights to identify potential failure points, optimise designs, and verify compliance with performance requirements.

Partner with Megagenix to support reliable, efficient, and informed engineering decisions throughout the design and development process.

Our FEA Services

With our FEA services, we help construction teams and organisations in Singapore with the following:

Structural Analysis

Evaluate stress, strain, fatigue, and deformation under a range of loading conditions.

Modal Analysis

Identify natural frequencies and vibration behaviour of structures and components.

Linear and Nonlinear Static Analysis

Analyse structural response under static loads, including complex and nonlinear behaviour.

Dynamic Analysis

Simulate time-dependent and transient loading conditions.

Thermal Analysis

Assess heat transfer through conduction, convection, and radiation.

Fatigue Analysis

Evaluates life, damage, and safety factors for high-cycle, low-cycle, and vibration fatigue under repetitive loading using stress-life and strain-life relationships.

Evaluate Complex Geometries

FEA allows detailed analysis of intricate and irregular structures that are difficult or impractical to evaluate using traditional calculation methods.

Simulate Multiple Physics

Engineers can model and study multiple physical behaviours simultaneously, gaining a comprehensive understanding of structural performance.

Save resources and time

By reducing reliance on physical prototyping, FEA enables early evaluation of safety, reliability, and performance, well before construction or fabrication begins.

Why Choose Megagenix as Your FEA Service Provider?

Quicker Quality

Product Development

Our simulation-driven approach supports faster iterations and informed design improvements without compromising quality.

Expert FEA

Service Provider

Our team brings strong analytical expertise and structured engineering methodologies to every project.

Real-World

Experience

We apply practical engineering knowledge to ensure simulations reflect real operating conditions and design intent.

Professional

Tools

We utilise industry-standard FEA software and tools to deliver reliable, high-quality simulation results.

Stages of Finite Element Analysis

When you engage in our Finite Element Analysis services, these are the typical stages of our work process:

The pre-processing stage establishes the foundation for the analysis and includes the following steps:

- Geometry and Mesh Generation: The system geometry is defined by importing an existing CAD model or creating it directly within the analysis software. The geometry is then divided into a mesh of finite elements that represent the system’s physical domain.

- Material Properties: Relevant material properties, such as elasticity, thermal conductivity, or fluid behaviour, are assigned to accurately reflect the physical characteristics of each component.

- Boundary Conditions: Constraints, loads, and other boundary conditions are applied to represent how the system interacts with external forces and its surrounding environment.

- Element Selection: Suitable element types, such as beam, shell, or solid elements, are selected based on the nature of the problem and the expected structural or physical behaviour.

During the solution stage, the mathematical model is solved to obtain the system’s response:

- Equation Assembly: Governing equations describing the system’s behaviour, such as structural equilibrium or heat transfer equations, are assembled into a global system based on the finite element discretisation.

- Numerical Solution: Numerical techniques, including direct or iterative solvers, are used to compute unknown values such as displacements, temperatures, or fluid velocities.

The post-processing stage focuses on interpreting and evaluating the results:

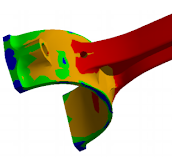

- Visualisation: Results are presented through contour plots, deformation animations, and stress or temperature maps to aid understanding of system behaviour.

- Quantitative Evaluation: Key results, such as maximum stress, displacement, or heat flux, are extracted and compared against design requirements or performance criteria.

- Sensitivity Analysis and Optimisation: Additional evaluations may be performed to study the influence of design parameters or to refine the system’s performance.

Our FEA Case Studies

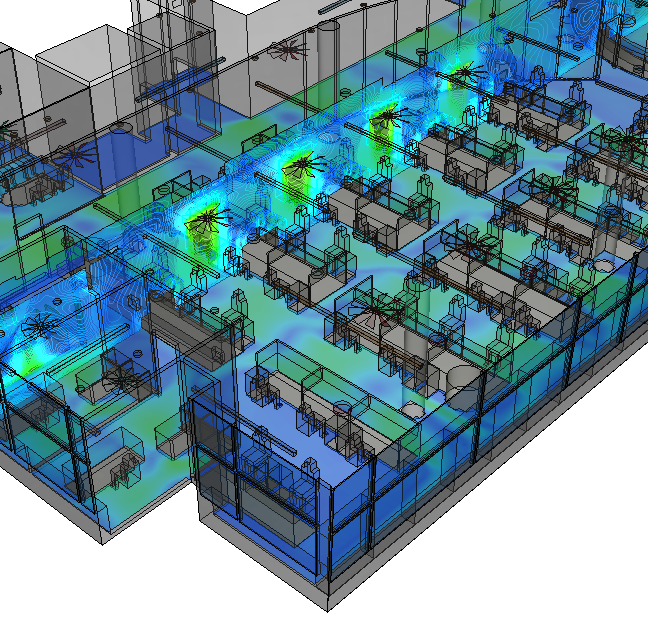

Hybrid Cooling CFD Simulation

Check out this Computational Fluid Dynamics (CFD) analysis from Megagenix, which evaluated the thermal comfort of a room with a hybrid cooling system.

Find Out More >

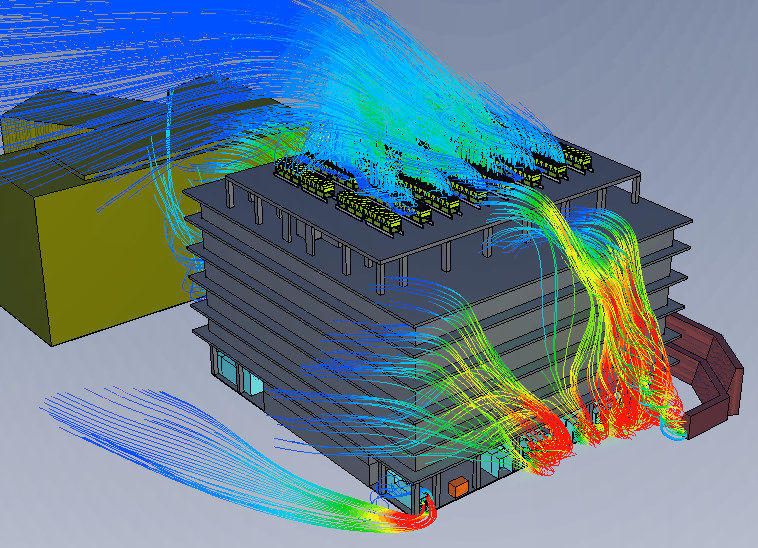

CFD Simulation Sample For Generator Set

Learn how CFD analysis can help assess the functionality of a generator set, identifying potential heat distribution issues and ensuring safe operation.

Find Out More >

CFD Simulation Sample for Data Centers

Optimize data center cooling with CFD simulations to predict airflow, prevent hotspots, enhance energy-efficiency, ensuring sustainable operations.

Find Out More >

FEA Simulation Sample for Roofing Structure

Check out our Finite Element Analysis of a roofing structure, evaluating its deformation, stress, and structural safety.

Find Out More >

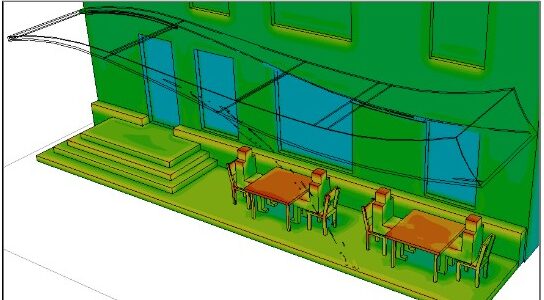

CFD Simulation Sample for Roofing Structure

Check out this CFD simulation analysis of a roofing structure, evaluating its thermal and shading performance.

Find Out More >

FEA vs Traditional Prototyping

| Finite Elements Analysis | Traditional Prototyping | |

|---|---|---|

| Cost | Lower overall development cost | High cost due to multiple prototypes required |

| Time Efficiency | Faster design validation | Potentially longer development timelines |

| Accuracy | High-resolution insight into internal behaviour | Limited to measured test points |

| Number of Iterations | Multiple virtual iterations possible | Depends on cost and time |

| Suitability | Works well with complex shapes and load conditions. | Great for initial design and feasibility checks. |

Industrial Applications of FEA in Singapore

FEA is widely used across by various professions and industries, including:

Mechanical

Engineering

FEA is extensively applied for structural analysis, helping assess the strength, stiffness, and deformation of components and systems.

Civil

Engineering

Civil engineers use FEA to evaluate an infrastructure’s structural integrity, stability, and load-bearing capacity, ensuring safe and efficient construction.

Aerospace

Engineering

In the aerospace industry, FEA is essential for analysing aircraft components to ensure structural integrity, predict fatigue life, and aid in performance enhancement.

Automotive

Engineering

FEA helps automotive engineers assess crashworthiness, vibration, noise, and overall performance of vehicle components and systems, including chassis, suspension, engine parts, and safety systems.

Energy Industry

Professionals

It is used for structural assessments, thermal analysis, fluid dynamics, and improving energy efficiency of power plants, wind turbines, pipelines, and other energy systems.

Electronics and Electrical

Engineering

In electronics, FEA evaluates thermal management, electromagnetic behaviour, and the structural integrity of components, circuit boards, and power distribution systems.

Biomedical

Engineering

FEA assists in the design and analysis of medical devices, prosthetics, implants, and biological systems, helping predict stress distribution, fluid flow, and biomechanical performance.

Manufacturing

Industry

FEA can be used to optimise manufacturing processes by assessing the structural integrity of equipment and simulating material behaviour during forming, machining, or casting operations.

Frequently Asked Questions on FEA Services in Singapore

What types of analyses does FEA cover?

Our FEA services cover structural analysis, modal analysis, linear and nonlinear static analysis, dynamic analysis, thermal analysis, and mould flow analysis.

Can FEA handle complex geometries or nonlinear behaviours?

Yes, FEA is well-suited for complex geometries and nonlinear material or contact behavior.

How much does FEA consulting cost?

The cost depends on project complexity, scope, and analysis requirements.

How long does an FEA project take?

Project timelines vary based on model complexity, number of load cases, and required iterations.

What deliverables will I receive from FEA services?

Typical deliverables include detailed reports, contour plots, assumptions, and engineering recommendations.

How accurate are FEA results?

Accuracy depends on input data, modeling assumptions, and boundary conditions, all of which are carefully defined during analysis.

Do you validate FEA models experimentally?

FEA results can be compared with test data when available to improve confidence and accuracy.

What if FEA results show design flaws?

Identified issues can be addressed early through design modifications and re-analysis.

Can FEA integrate with my CAD or existing team?

Yes, FEA workflows commonly integrate with CAD data and existing engineering teams.

Is FEA suitable for my industry?

FEA is applicable to most industries where performance, safety, and reliability are critical.

How do I get started with FEA services?

You can start by discussing your design objectives, challenges, and requirements with our team. We will then work closely with you to understand your project needs and recommend the most suitable FEA approach. From there, we develop a tailored simulation plan, set up the models, and guide you through each stage to ensure accurate, actionable results.

We can also provide thermal CFD analysis along with our FEA services. Work with our FEA and CFD consultants in Singapore today.